Instalación le PTO Chelsea & Náakake' u yaak'il ti' operaciones

Bix u meyaj P.T.O.: Engranajes, Paso engranaje xma' relación yéetel relación

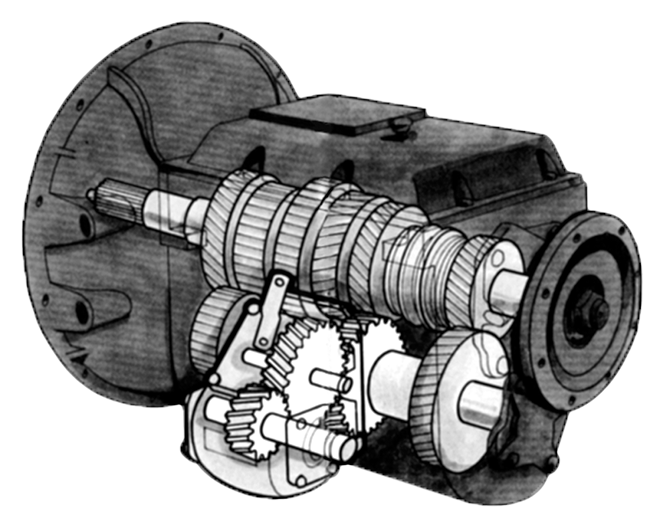

Le típico Chelsea P.T.O. meenta'an yo'osal ch'a'abil teen u potencia le kisbuuts'o', ti' le rotación, and transfer it to another piece of equipment. They are mechanical gearboxes that attach to an opening provided on truck transmissions and are used to transfer the power of the vehicle engine to auxiliary components, asab comúnmente jump'éel bomba hidráulica. The hydraulic flow generated by the pump is then directed to cylinders and/or hydraulic motors to increase performance. Le linki abas kaambal ti' explicará términos importantes yo'osal u instalación yéetel operación ti' Chelsea PTO.

Je'el u páajtal u descargar le náakake' u yaak'il ti' operaciones u PTO Chelsea beetik clic waye'.Wa k'áabet áantaj utia'al identificar u Páajtal a PTO Chelsea ts'a ti' máax ku k expertos ti' 877-776-4600 o 407-872-1901 wa uláak' ba'alo'obe' xíimbalt k linki abas kaambal u nu'ukulo'ob páajtal a.

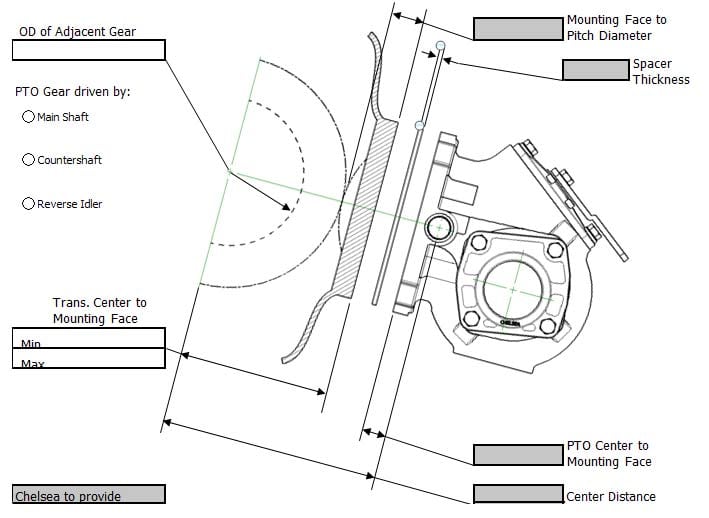

Le nu'ukulil ke u jump'éel instalación TPes le le engranaje, wa diseño u nu'ukulo'ob engranajes.

Le rotación ku Mool yo'osal mallado ti' engranajes wa acoplamiento yéetel uláak' engranajes, utia'al u Chelsea P.T.O. meyaj, the gears must mesh properly with the transmission’s PTO drive gear. U u beeta'al jump'éel instalación TTO, Jach jach Páaybe'en, utia'al u K'ajóolt le diseño yéetel le especificaciones kojo'ob le engranaje ti' yaantal.

Términos importantes u despegue energía

- Juntúul engranaje espolón ma' u malla adecuadamente yéetel juntúul engranaje helicoidal

- Helical gears not only must mesh with each other, Ba'ale' juntúule' k'a'ana'an u diestro yéetel le uláak' k'a'ana'an u zurdo

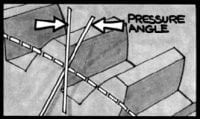

- Le engranajes helicoidales xan k'a'abéet yaantal le ti' jump'éelili' kuchil-construcción koj tu términos paso, ángulo presión yéetel ángulo hélice

- Le ángulo hélice le u grado u ángulo u k'oosik ti' le engranaje

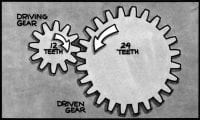

- Le relación engranajes le uláak' tu'ux k'a'abéet u P.T.O. Meyajo'ob. The P.T.O. relación u yaantal je'el u páajtal u modificar le velocidad funcionamiento le kisbuuts'o' u requisitos le dispositivo p.T.O.

- Le yáax P.T.O. Bix u le Buka'aj u ba'al u xanab k'a'abeto'ob yéetel le velocidad funcionamiento ku asab chika'an satisface kajtalo'ob ichil u le ka'anatako'ob

- Kex le relación engranajes ti' le ejemplo ts'áaik ka'achij 2 Utia'al 1, le k'eexpajal ti' le xanab le 1 Utia'al 2. Le je'ela' ku k'uchul u dividiendo u meyaj ku h ti' le engranaje accionado: 12 ÷ 24 = 0.5 (1 Utia'al 2).

Supongamos u potencia le kisbuuts'o' ba'axi' 50 yéetel u velocidad le chan marcha 1000 revoluciones tumen minuto (Rpm.).

Le fórmula utia'al u determinar le xanab le:

T'aano' - Potencia u potencia x 5252 Velocidad (Rpm.)/Velocidad (Rpm.)

(Sm) 50 x 5252 = 262.6 Libras. Wook. Xanab / 1000

(Lg) 50 x 5252 = 525.2 Libras. Wook. Xanab / 500

Páaybe'en:

Ba'ale' wa, le situación invirtió yéetel u nojochil engranaje u impulsa le marcha asab chichanen, le engranaje Jach chichan giraría ka'atúul Óoxten asab séeba'an u nojochil le engranaje, Ba'ale' le xanab giraría ka'atúul Óoxten asab séeba'an u nojochil le engranaje, Ba'ale' le xanab sería chéen chúumuk nojoch.

Nu'ukulil

Le TTO utilizan ti' ya'ab aplicaciones. Le tipos nu'ukulo'ob náats'al ba'ax ku benefician ti' jump'éel TP ku; Volquetes, remolques volquete, ch'óoy leti' máak montacargas, montacargas aéreos, camiones u bomberos yéetel meyajo'ob, rechazar camiones, camiones chupadores u vacío, camiones limpiadores u alcantarillado, camiones bombas ja' yaan producto, camiones reparto propano, snow plow/dump trucks, excavadoras gradall, camiones remolque yéetel asab.

PTO Installation to the pump

Use caution to ensure that the bracket does not pre-load pump/P.T.O. mounting

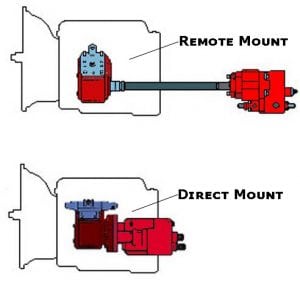

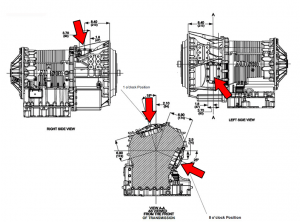

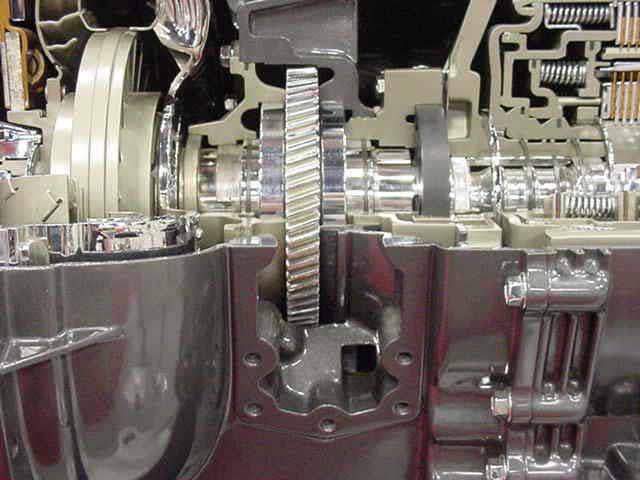

The most common power take-off in use is the sidemounted PTO, there are also models installed to the rear of specific transmissions and split shaft PTOs that are mounted by removing a section of the vehicle’s main driveline.

Rear-mounted PTOs are often called countershaft PTOs but many sidemounted PTOs are also driven by gears on the transmission’s countershaft. You may hear people refer to side countershaft and rear countershaft power take-offs to make a distinction. The transmissions commonly found in class 4 and larger vehicles will have provisions for the PTO installation.

Generally there are two apertures, one on each side of the transmission(some smaller transmissions may have one). Many Eaton Fuller transmissions have a PTO aperture on the bottom (offset to the left), and some Allison automatic transmissions have a top aperture.

Your Chelsea PTO may be engaged by a cable, lever, air pressure, or hydraulic pressure. Recent PTOs use a small electric motor and hydraulic pump inside the shift cover assembly to provide hydraulic force to engage the PTO. There are various output shaft configurations available for a driveshaft connection or the pump attachment, directly to the PTO, without an intermediate shaft. The Society of Automotive Engineers (S.A.E.) has established standard mounting face dimensions for pumps and PTOs are made to accept these. These are referred to, from smallest to largest, as the S.A.E. A, B, D, E and F

In a direct mount the hydraulic pump is mounted directly to the output flange of the PTO. Direct mounting is the most common type of PTO in the mobile equipment industry. A concern to be wary of when direct mounting a pump is a condition known as shaft fretting. This is rapid spline wear of the PTO and pump shafts. The wear is evident at the place in which the two metal surfaces come into contact with each other, as the micro-movement of the two surfaces against one another wears each surface. When direct mounting a pump you must do the following:

- Specify a PTO output shaft and mounting flange that match those of the pump.

- Select the correct pump rotation to match the PTO output rotation or select what is known as a bi-rotational pump, which tends to have equally sized ports since either can be the inlet or outlet.

- Provide a rear pump bracket to support the weight of the pump.

Sometimes it is not possible to direct mount a hydraulic pump, requiring the pump to be attached using a remote mount method. In a remote mount the pump is away from the PTO and powered from the power take-off by using a driveline assembly. Solid shafting is not recommended because it can’t be balanced and can vibrate. This leads to damage to the PTO and pump shaft seals. A balanced, tubular assembly designed to meet the speed, torque and horsepower requirements of the application is the best choice.

If using a driveline, it’s important for it to be in phase and incorporates a slip yoke at one end. Round, keyed PTO output shafts are susceptible to failure by high cyclic loading. An out of phase shaft will vibrate and damage the PTO and pump shaft seals while a functioning slip yoke will allow the shaft to adjust for flexing of the truck chassis.

Supporting the pump

Chelsea strongly recommends the use of pump supports (Support Brackets) in all applications.

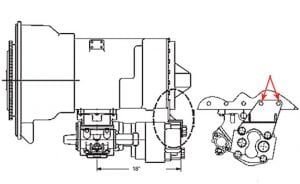

When using a direct mount method, in PTO installation, use a support bracket to support the pump to the transmission when the following conditions apply:

- The pump weight 40 pounds or more

- The combined length of the PTO and pump reaches or exceeds 18 inches from the PTO centerline to the end of the pump

ALSO: Remember to pack the female pilot of the P.T.O. pump shaft with grease before installing the pump on the P.T.O. (reference Chelsea grease pack 379688)

Páaybe'en: For proper bracketing, adjuntar ti' 2 wa asab ubicaciones pernos yaantal yéetel 2 wa asab ubicaciones bombeo. Fabricación u Máax ku utia'al u ubicaciones u montaje bix u ti'alo'ob yaantal. Yanak ti' Bik utia'al asegurar ti' u le bix ma' precargue u montaje le bomba leti' PTO.

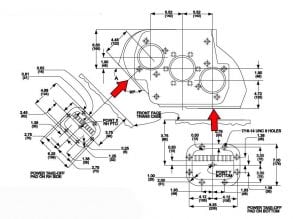

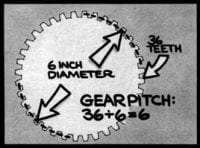

Juntúul engranaje cuyos koj u ch'áak' Jun ti' u yich le engranaje.

Juntúul engranaje cuyos koj u ch'áak' Jun ti' u yich le engranaje.

Le engranajes helicoidales páajtal u yaantal u kojo'ob yéetel juntúul inclinación diestra wa zurda.

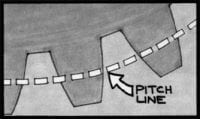

Le engranajes helicoidales páajtal u yaantal u kojo'ob yéetel juntúul inclinación diestra wa zurda. Distancia ti' u chúumukil le engranaje medida tak le internet ichil paso jump'éel koj tak le internet ichil paso koj Jun kíinsa'ab tu táan le koj.

Distancia ti' u chúumukil le engranaje medida tak le internet ichil paso jump'éel koj tak le internet ichil paso koj Jun kíinsa'ab tu táan le koj. Medición le Buka'aj kojo'ob engranaje determinado tumen le meyaj ku kojo'ob ti' jump'éel kúuchil determinada medida ti' le internet ichil paso. P.T.O. paso engranaje u clasifica normalmente bey

Medición le Buka'aj kojo'ob engranaje determinado tumen le meyaj ku kojo'ob ti' jump'éel kúuchil determinada medida ti' le internet ichil paso. P.T.O. paso engranaje u clasifica normalmente bey Angulo formado, medidos tu grados, Tuméen juntúul internet ichil dibujada perpendicular ti' le internet ichil paso, yéetel juntúul dibujada tak le k'iino' je'el xano' ch'aaj ti' le internet ichil paso tangente ti' le perfil koj internet tu'ux ichil.

Angulo formado, medidos tu grados, Tuméen juntúul internet ichil dibujada perpendicular ti' le internet ichil paso, yéetel juntúul dibujada tak le k'iino' je'el xano' ch'aaj ti' le internet ichil paso tangente ti' le perfil koj internet tu'ux ichil. Le relación engranajes determina u dividiendo le meyaj ku kojo'ob ti' le engranaje accionado tumen le meyaj ku kojo'ob ti' le nu'ukulil conducción

Le relación engranajes determina u dividiendo le meyaj ku kojo'ob ti' le engranaje accionado tumen le meyaj ku kojo'ob ti' le nu'ukulil conducción Le ch'aaj ti' koj le engranaje chúumuk bej ichil le k'oja'ano'obo' koj xnuk koj..

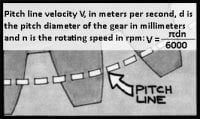

Le ch'aaj ti' koj le engranaje chúumuk bej ichil le k'oja'ano'obo' koj xnuk koj.. Le velocidad ku rotación tin wook tumen minuto jump'éel engranaje medido ti' le internet ichil paso,

Le velocidad ku rotación tin wook tumen minuto jump'éel engranaje medido ti' le internet ichil paso,